Globally recognised as a leader in the manufacture and supply of castings and fabrications that are unsurpassed in quality and integrity.

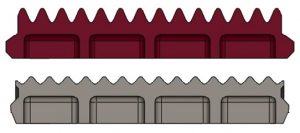

Foothills Steel Foundry has the capability to design and engineer quality cast steel wear parts as well as a variety of martensitic high chrome white iron products for the mining industry on a global scale.

Quality is a massive part of our process, it’s our end game. We only deliver parts that we know have integrity. Because we start with the end in mind we are now known as a global leader for some of the best wear parts in the world. It’s a big claim but one we are prepared to back.

With our recent ISO certification we can prove it too. Over the years our capability has increased year on year. The size of our operations has increased and our workforce has increased. As a proud Canadian Foundry with a long heritage and big plans we look forward to what the future holds.

Our aim is to offer the market alternative and more reliable solutions to OEM parts and to ensure that any forced downtime experienced by our clients is minimised through the creation of quality parts that not only last longer and are supplied on time, but also at a reduced cost. Proprietary Alloys, linear delivery solutions and our global supply chain helps us to achieve this.

Talk to us about your next order of wear parts of custom cast solutions.

#foothills #foothillssteel #wearparts #qualitymanagement #manufacturing #downtimereduction #wearpartsthatlast

Foothills Steel Foundry has the capability to measure, design and cast anything steel, and it is liberating.

Foothills Steel Foundry has the capability to measure, design and cast anything steel, and it is liberating.