Wear Parts

Our large range of alloys and on staff metallurgists result in FSF wear parts meeting or exceeding OEM.

Foothills have been servicing the Crushing and Mining Industry for 70 years. We intrinsically understand wear parts and the problems you face with changeout or downtime.

Prepare for changeout

When downtime hits it hurts both output and your profit. We know you need to rely on your plant and equipment to get the job done and that means having a foundry partner working alongside your site personnel to help you solve critical wear problems before they arise

By combining over 70 years of experience with advanced performance monitoring techniques we can assess and analyse your operation so we know what will wear out and when. Just in time deliveries overlaid on your scheduled maintenance programs equals reduced downtimes, smoother maintenance turnarounds and less overall costs.

Our Services

We manufacture customized cast wear parts for almost any industry.

We have the ability to reverse engineer solutions and design new parts to solve onsite problems, this makes us very versatile and adaptable.

Having such vast experience means that we know how to solve every conceivable wear part problem on site.

Ask us for our expert opinion.

Cone Liners

Produced from Hadfield Manganese, the Foothills Steel Foundry Cone Crusher Liners are harder and tougher than any other liner on the market today.

Designed to withstand enormous amounts of impact stress, the cone crusher liner can be manufactured with up to 24% Manganese alloy content.

Impact Blow Bars

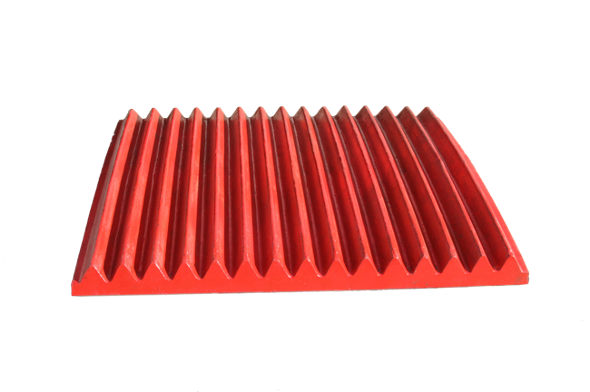

Jaw Crushers

We can supply jaw crusher liners to suit any brand machine. Keep your crushing operation productive by ensuring you have stock of your Jaw liners.