Complete Pipe Spool Solutions

Foothills is ABSA Certified

Being ABSA certified means that as a manufacturer of all components in the manufacturing process, we have complete control over the quality, delivery and maintenance of our pressure vessels. This means that we are your complete One Stop Shop for all Pipe Spool requirements.

-

We have the capability to

-

- Weld Pipe Spooling

-

- Machine Pipe Spooling

-

- Build Pipe Spooling

-

We can also

-

- Replace spool rubber liners with our high chrome white iron centrifugal cast inserts

-

SAVING YOU TIME, MONEY AND DOWNTIME

-

- Better dimensional accuracy over the length of spool

- Better roundness (no oval shapes)

- Allows for seamless chrome insert to achieve max thickness (increase insert OD to close the gap between round ID of seamless shell and round OD of insert)

- Better wear profiles achieved through better concentricity of insert to spool

- Easier to clean backing material

Pipe Spool Services

We have been pursuing alloy improvements for over 70 years. At Foothills we consider ourselves as out of the box thinkers and collaborators with multi industry experience. We are willing to invest in and pursue alternative alloys and techniques to reach a robust solution that is fit for purpose. Using our large network of suppliers both domestically and offshore we can engineer the solution to your pipe spool problems.

Facility Capabilities

-

- CUSTOM MACHINING AND FABRICATION

-

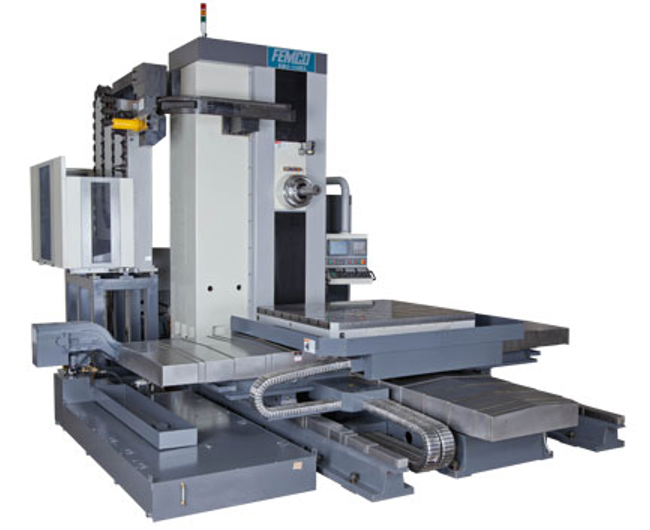

- DUAL COULUMN VERTICAL BORING MILLS

-

- TURRET LATHE FOR MACHINING CYCLONE INSERTS

-

- 5 AXIS HORIZONTAL MILLING CENTER

-

- NEOPRENE REMOVAL

-

- HORIZONTAL TABLE PLANERS

-

- ACCURAL CPL 6025 XPR300 CNC PLASMA CUTTER

-

- LINMAC PLATE ROLLER

Products to manage spool replacements

We work with you to custom machine pipe spool solutions that last longer and keep you operating efficiently and profitably.

At Foothills we have a number of products to help manage your spooling more effectively including high tech sensors to identify wear, & high chrome inserts to replace neoprene or rubber inserts.

Our innovative solutions mean that your spool sections last longer, reducing the capital cost of replacement and a reduction in down time.

CNC Plasma Cutter

Dual Column vertical boring mill

Linmac Plate Roller

5 Axis Horizontal Milling Center

Horizontal Table Planer

Neoprene Removal

Development Products

-

Currently we have several development products in the make.

- Pipe Spools

- Centrifugal Cast Pipe Spool Inserts

- Flow T Elbows

- CCO Spool Overlays

FSF Pipe Spool Sensor Package

- Accurately monitor pipe spool insert wear rates

- Daisy Chain capacity on large build out

- Accurately predict pipe turning or replacement

- High cost can be absorbed through savings in other processes (spool fabrication and inserts)

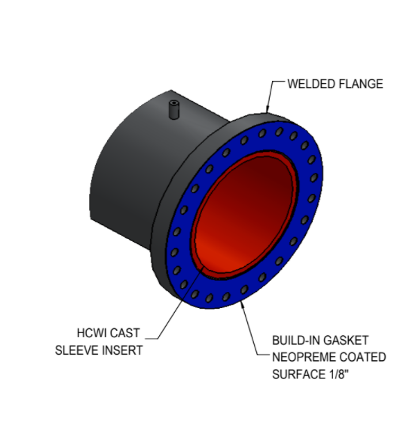

Centrifugal Cast HCWI Insert

- Centrifugal cast to remove all conventional sand casting defects

- Complete repeatability due to process type

- Combined effort of 3 corporations, off shore and locally in order to manufacture

- Large scale wear life improvement vs Neoprene

- Target: overall price within 10% of neoprene lined spools

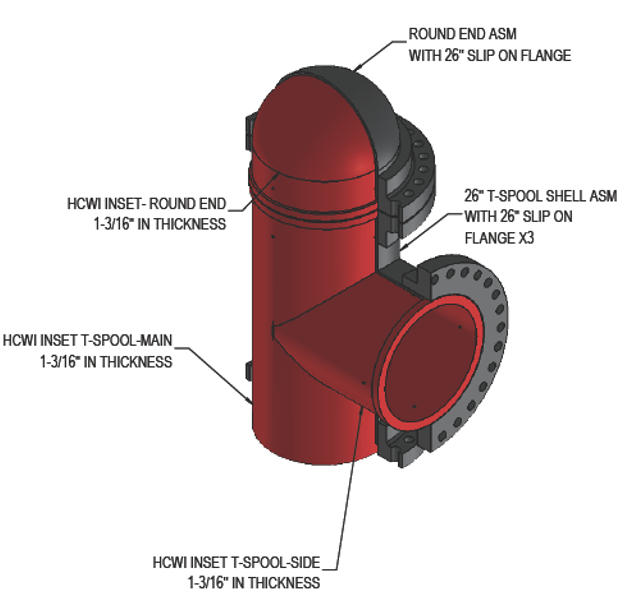

Flow T Pipe Connection

- This replaces the Elbow

- Works on backpressure, creating “slurry on slurry” wear profile

- Utilizes sectioned centrifugal insert

- HCWI “cap” easily removed and replaced

- Already heavily utilized in conventional drilling platforms

Chrome Carbide Pipe Spool Overlays

- CNC Controlled Open Arc overlay, designed to meet producer CCO Specification

- 20’ travel capacity

- 36” Diameter pipe Capacity

- Locally installed (FSF Calgary)

- Repeatable through CNC programming

- Modular design capable of overlays anywhere with power/ventilation capacity

- Purchased December 01 2020

- Installation targeted 1st Quarter 2021

- Target: Min 30% cost saving

- Rebuild all welded seam spools while FSF replaces with seamless design

Spool Flanges

- Flanges Sourced offshore through FSF Network, Welding done internally in order to conform to ABSA (Alberta Boilers Safety Association)

- Engineering monitored and controlled by FSF

- All testing done locally per producer specification to ensure conformance

Chrome Carbide Pipe Spool Overlays

With miles of pipe to manage and wear a real challenge in the OilSands industry it is important to know what innovations have arisen that can assist you with maximising your assets to their full potential.

Instead of replacing your pipes or re lining them with neoprene why not consider re lining the pipes with High Chrome, it last hundreds of hours longer and can be re lined time and time again.

-

- CNC Controlled Open Arc overlay, designed to meet Specification

- 20’ travel capacity

- 36” Diameter pipe Capacity

- Locally installed (FSF Calgary)

- Repeatable through CNC

- Modular design capable of overlays anywhere with power/ventilation capacity

- Rebuild all welded seam spools while FSF replaces with seamless design

-