Design & Engineering

Foothills Steel Foundry offers a full Engineering Design service.

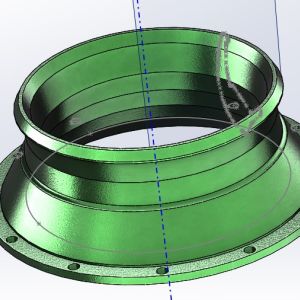

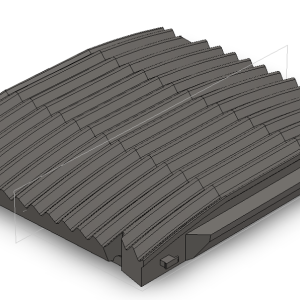

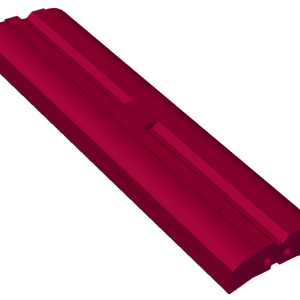

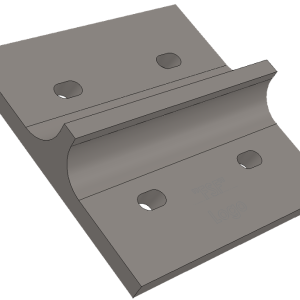

We use Solidworks in-house as our CAD platform, and our design engineers are able to take a product from a sketch or a sample through our full manufacturing process.

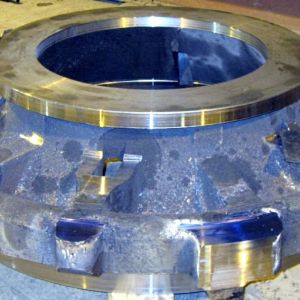

To assist with the initial dimensions, we are able to digitally measure new or worn samples with our Faro Arm CMM or Creaform Laser Scanner. Both these tools are accurate to 0.04mm (0.0015″), and the measurements are imported directly into Solidworks.

Our engineers can also convert sketches, paper drawings or AutoCAD files and models in the Solidworks format.

Once we have an accurate 3D model, we then start our manufacturing process.

Foothills engineers are also able to measure wear profiles on worn parts, and compare them to new parts. Using the information gathered in this process, we can optimise the design of replacement parts to extend their wear life.

Design Services

The Foothills brand is synonymous with hard wearing and long lasting quality parts, and part of the reason is that we have the best tools to carry out the job and an experienced team who know their stuff. With over 70 years of experience and a bounty of technology, our reputation is well deserved.

We have a variety of scanners and technological measuring tools to help us ensure the parts we measure are an exact fit. We can measure your equipment to manufacture a part that fits in your machine with 100% precision.